From the beginning to the present

2011

Martin Varga is trying to bake his first muesli bars at home in the kitchen. He needed them for his mountain climbing trips, as his heavy consumption of conventional biscuits gave him stomach problems.

2012

The first orders from his fellow climbers are coming in, just based on tastings. The customer base is gradually growing.

2013

First attempts raw bars of dates and nuts. Destroyed blenders. First professional blender purchased on eBay. Fresh RAW bars taste incomparably better than conventional ones.

2013

december

Martin Varga establishes MARVA s.r.o. Košice. The name was invented by Martin's father - MARtin VArga. Martin is gradually arranging the necessary permits for the reconstruction of the garage and the adjacent basement of his parents' house, where he plans to set up a new production.

2014

2015

2016

We are switching to smaller packages - 75g. New labels, EAN codes, vacuum packaging. The offer is growing with new flavours: Muesli Extra Dark 72%, Raw Poppy with lemon. We are introducing a complete novelty - naturally gluten-free buckwheat bars. A new team member joins our team - Inga Bázliková.

2017

We are purchasing a new powerful 3kW Robot Coupe mixer and a new dough kneader. Special treatment of the equipment surfaces with non-stick coatings, for processing RAW bars. We are gradually increasing production output as demand increases. We supply over 80 retailer outlets. Still hand production - hand slicing, forming, wrapping, labeling. Shelf life is limited to 3 months.

2018

We acquire new business partners Yeme, Fajne potraviny, Starý otec., TMR etc. We are successfully presenting the bars at festivals and events. The bars travel around the world with our ambassadors. Caucasus, Peru, El Capitan, Sydney... New flavours Raw Ginger, Raw Cocoa with Chilli, Muesli Apple Cinnamon are being added.

2019

July

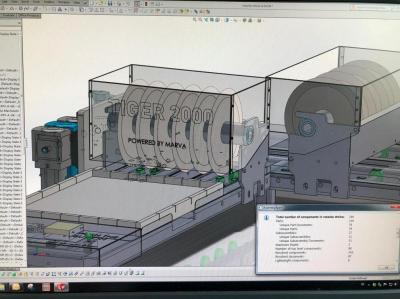

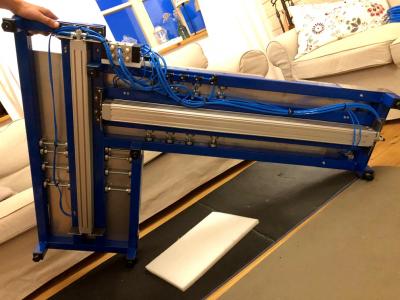

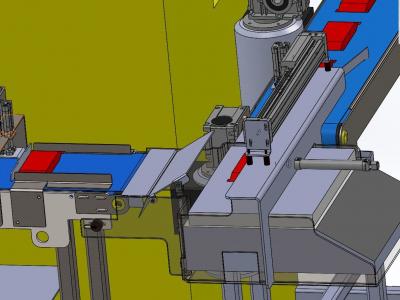

We are switching to smaller packaging - the market has demanded the standard 50g. New dough moulds, new bar shape. Within three months Martin designs and manufactures the Festo pneumatically driven automatic dough bar cutter. This means no more manual cutting, increased precision and increased production output.

2019

September

After half a year of research and testing of new foils, we are investing in a new horizontal wrapper. This wrapper has 10 times the performance of vacuum wrapping. We are switching to a new high-barrier transparent foil that allows us to extend the shelf life of products without changing the recipe and without adding preservatives. Extending shelf life to 6 months is a fundamental change in retail success.

2020

February

2020

April

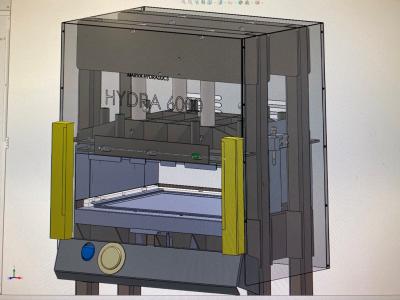

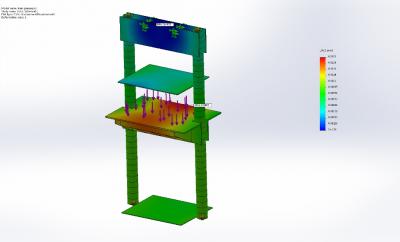

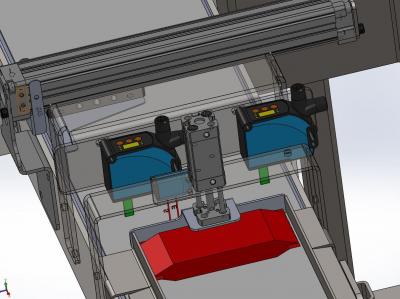

Martin, in cooperation with his father, launches a hydraulic press. It took eight months to design, FEA optimization, manufacture and assembly of the dough forming press. This replaces manual rolling with a mould roller, one of the most demanding tasks during production. It can operate in manual and automatic mode, with adjustable clamping force, which is different for muesli, raw and buckwheat doughs. The press has undergone extended testing and optimization to increase the accuracy of the desired dough thickness. It dispenses an optical barrier for maximum work safety.

2020

October

Another process requiring automatization is weighing. The automatic weighing scale is ready after only three months. It is a simple device, but essential for quality control at the output. Bars that do not meet the weight limit set by legislation are sorted automatically after packaging. The in-house designed scale replaces conventional machines that are many times more expensive.

2020

December

New printed foils are coming! After ten months of design, calculations and production. This eliminates the manual double-sided labelling of paper labels. The new packaging looks professional and - most importantly - is recyclable. At the same time the results of long-term tests from an accredited laboratory are coming - shelf life is safe for 9 months.

2021

January

Due to the COVID-19 pandemic there is a second lockdown in Slovakia. Martin is using his time to design two new machines. These are an infeed conveyor, which relieves the operator at the entrance to the packaging machine, and an automatic cartoner, which counts and fills cartons of bars in 24pcs. At the same time, it checks the welds and discards sticks with a defect in the weld. MARVA is also donating 1,920 bars to the Košice Ambulance Service and the Louis Pasteur University Hospital.